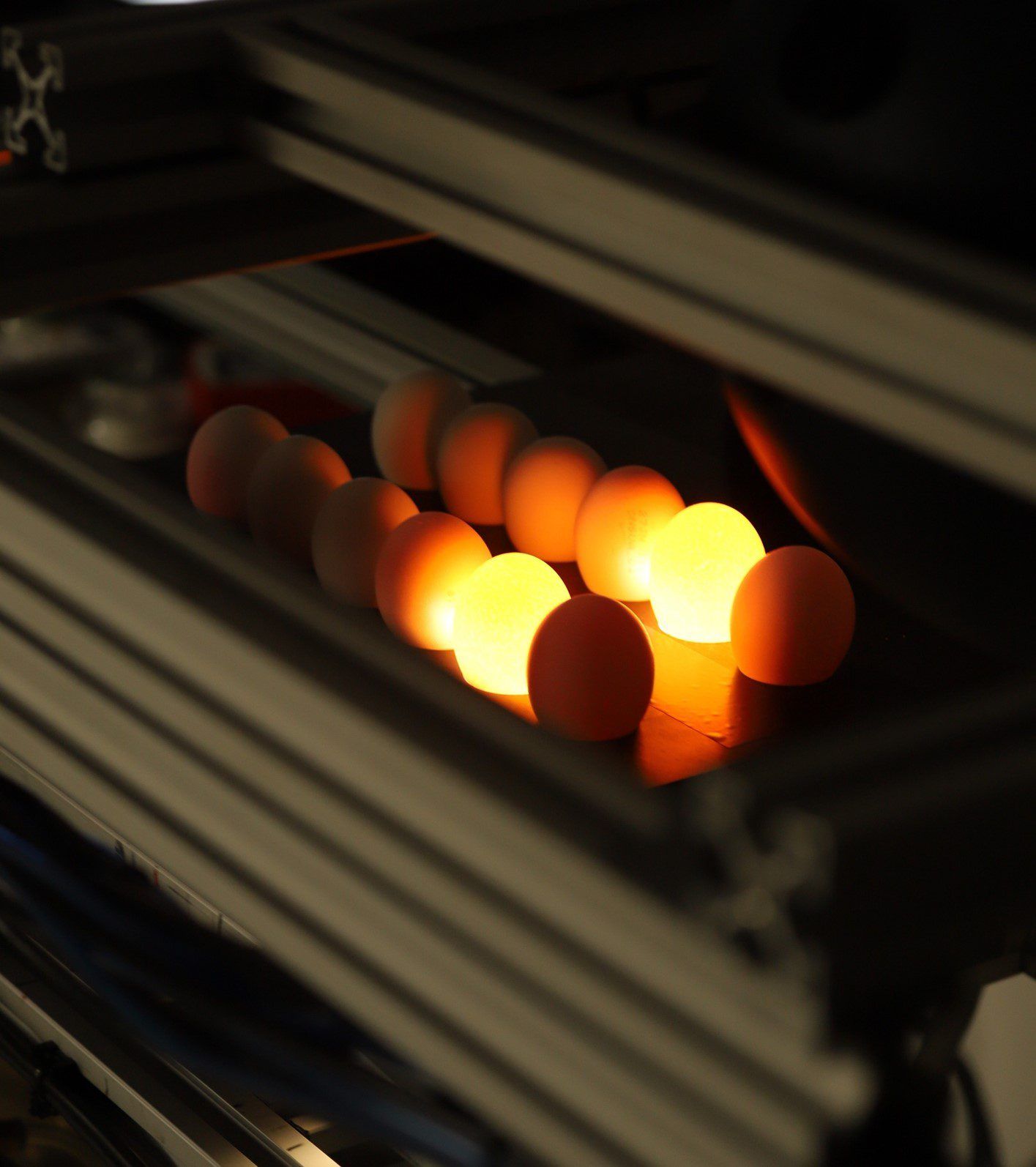

“Hyper eyes” that can see inside eggs

Two Canadian egg organizations and a technology company have developed an in-ovo sexing technology that can be used on both white and brown eggs and will soon be marketed to egg producers.

The HyperEye technology uses a combination of hyperspectral imaging and artificial intelligence and works on all eggs as early as the fourth day of incubation. The non-invasive method has been validated in commercial hatcheries.

The HyperEye technology is stand-alone and has a small footprint, making it able to be incorporated into a hatchery’s already existing process flow. The equipment was developed by Canadian Egg Technologies, a collaboration between Egg Farmers of Ontario and Egg Farmers of Canada, and technology company MatrixSpec Solutions.

“As farmers, we understand firsthand the need to continue to evolve our approach and use new innovations to address the challenges at hand,” stated Co-Chair of Canadian Egg Technologies Roger Pelissero. “HyperEye provides a unique solution for hatcheries world-wide and can help accelerate our collective efforts in addressing a complex area of our supply chain.”

Matrixspec CEO Dr. Michael Ngadi said: “Working directly with farmers has allowed us to understand the intricacies of hatcheries and the egg supply chain. Together, we are not only addressing animal welfare concerns but also offering a practical and scalable tool that is designed to integrate seamlessly into hatcheries.”