Research and Development

Our research and development activities are based on

- domestic and international technical literature,

- the results of research carried out by raw material manufacturers,

- nutrition experiments and our professionals’ and technicians’ practical experience

- and we also substantially rely on the technical / professional experience of the professionals and technicians of our partners.

Our premix and feed mixes recipes are developed on the basis of most recent research and practical results and international recommendations.

Pig farm at Lovászpatona

world class production results

The objectives of the construction of the test farm and its continued development in 2013, with a total capital expenditure of HUF 600 million:

- testing products before offering to partners at a farm of 200 sows,

- supplying our external orders for feed, pig farming technologies and animal health services, supporting product development projects.

Live piglets per farrowing | piglets / sow | 16,87 |

Fertilisation percentage | % | 95,31 |

Weaned piglets per sow per year | piglets / sow / year | 35,28 |

Sold fattening pigs per sow per year | piglets / sow / year | 33,86 |

Growers’ body weight gain (between days 26 and 72) | g / day | 510 |

Growers’ specific feed conversion | kg/kg | 1,52 |

Body weight gain at fattening farm | g / day | 968 |

Fattening pigs’ specific feed conversion | kg/kg | 2,63 |

Our new fixed investment projects

Fermentation plant in Szalkszentmárton

The objective of the project: to adapt and improve the innovative wet fermentation technology based on domestic grain and protein resources and their by-products to improve livestocks’ production and animal health status.

We also aim to extend the benefits of the fermented product to farms using dry feeding technology as well, by coating solid substrates with the fermented raw materials.

Start of project: mid-2021.

Creating new laboratory

Together with the construction of our fermentation plant at Szalkszentmárton in 2021 we also put in place a new laboratory of European standards in Hungary.

Our services will be available for both our partners and external clients. The analytical methods to be used will make it possible to efficiently and effectively support our partners’ work.

Construction of an experimental poultry farm

Besides its existing experimental pig farm, the Agrofeed Group is planning to construct a multifunctional experimental poultry farm complex to study the impacts of different technological parameters (besides nutrition) on productivity in three separate poultry keeping units simultaneously. Both the architectural solutions to be applied and the cutting edge technology to be installed will enable the maximised production in terms of volume and standards as well as economic efficiency. A special function of the prospective test farm is that its visitors’ centre will give an insight into the production processes as well.

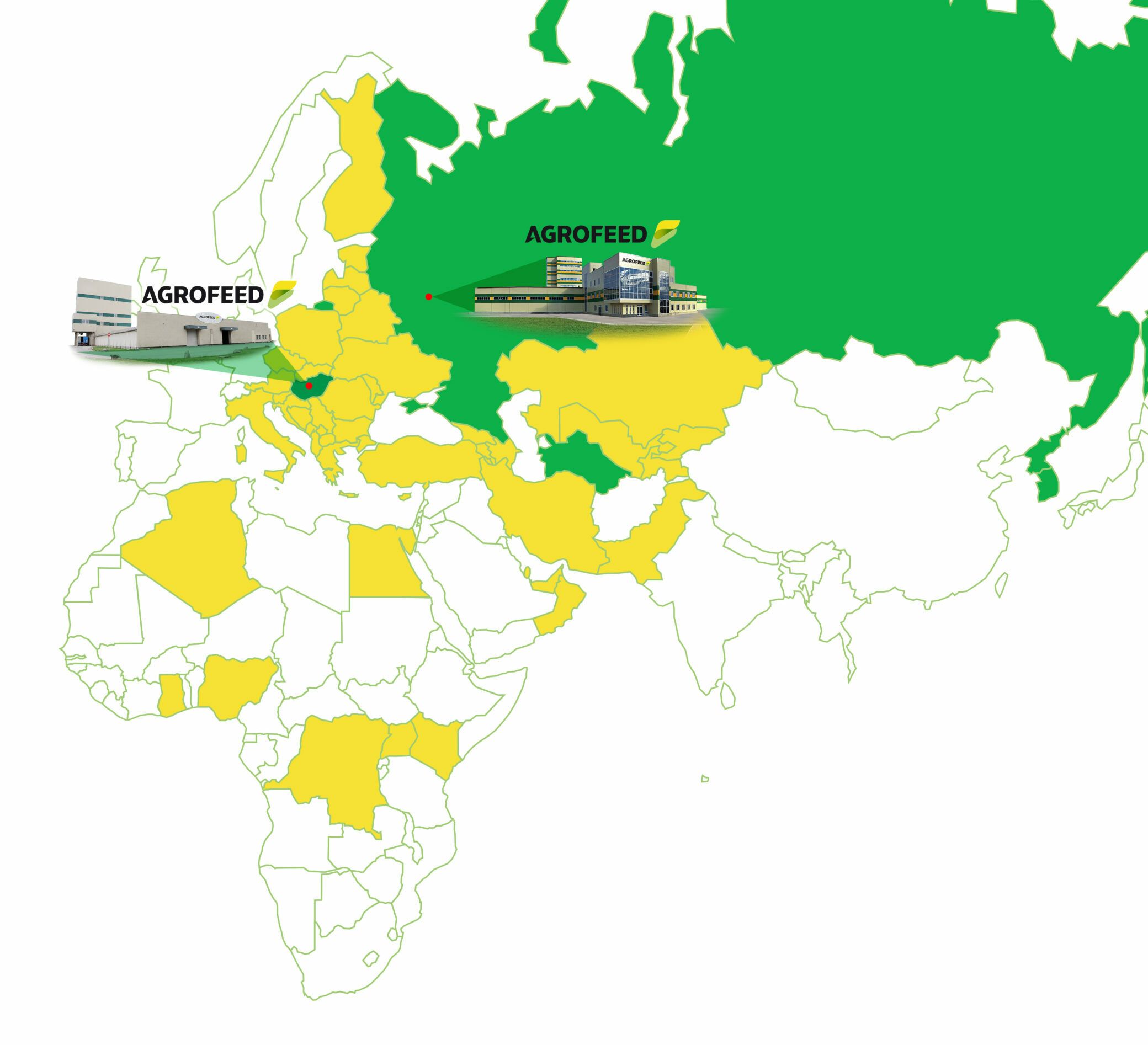

Our plants

Plant in Russia (Yasnogorsk)

2016 – Russia’s newest and most up-to-date premix manufacturing plant fully automated, vertical manufacturing line of a floor area of 1400 m2 a world class laboratory of a floor area of 250 m2.

Szalkszentmárton

2005 – One of Europe’s most up-to-date premix, concentrate and pre-starter plant was put in place

2010 – enhancement, modernisation

In both plants:

process controlling based on the use of bar codes

robotisation of processes

automated bag filling lines

comprehensive identifiability and traceability

Quality management

- application of accredited FAMI-QS V6 (GMP+, QS) and ISO 22000 (HACCP) systems of international recognition

- the quality management systems cover the entire process of product manufacturing and distribution, guaranteeing continuous, reliable quality

- use of the Navision corporate governance system for reliable traceability

- close collaboration with the internationally recognised LUFA laboratories.